Replaces

Rear Semi-Metallic Brake Pads TRQ BFA73712

BFA73712

This part doesn’t fit a . Select from parts that fit.

Specify your vehicle's year, make and model to guarantee fit.

This part does not fit a .

Frequently bought together

Specify your vehicle's year, make and model to guarantee fit.

This part does not fit a .

Part Details

- 0.55 in

- 14 mm

- 8 mm

- 0.31 in

- Yes

- Integrally Molded

- Yes

- No

- Yes

- 4.37 in

- 111 mm

- Contact Point Grease

- Hardware

- 1.81 in

- 46 mm

- No

- 4

- N

- Premium Posi

- Semi-Metallic

- Semi-metallic

- Mechanical

- Black

- Black

- 8 mm

- 0.31 in

- Yes

- Yes

- 1.81 in

- 46 mm

- Yes

- Yes

- 0.55 in

- 14 mm

- 4.37 in

- 111 mm

- Fiber

- Steel

- No

- Yes

About TRQ:

TRQ is a trusted brand dedicated to making every repair a success story by combining premium parts with easy installation. Each TRQ part is engineered by a team of automotive experts to meet or exceed OEM standards, delivering enhanced performance and maximum longevity. With rigorous in-house testing, the brand ensures superior fit and function across every product line. TRQ also provides customers with best-in-class, step-by-step installation videos—so you can complete repairs with confidence, whether you're a first-time DIYer or an industry professional.

Product Features

TRQ brake pads are manufactured using premium raw materials and design standards to restore original performance. TRQ brake pads are positive molded and utilize a multi-layer shim for enhanced performance and service life. TRQ’s combination of materials and design ensures a low dust and low noise braking experience. TRQ recommends replacing your brake rotors when you replace your brake pads to ensure even wear of components and improved braking comfort. All products are fit and road-tested in our Massachusetts R&D facility to ensure we deliver on our promise of Trusted Reliable Quality.

Attention California Customers:

![]() WARNING: This product can expose you to chemicals including Lead and Lead Compounds, which are known to the State of California to cause cancer, and birth defects or other reproductive harm. For more information, go to www.P65Warnings.ca.gov.

WARNING: This product can expose you to chemicals including Lead and Lead Compounds, which are known to the State of California to cause cancer, and birth defects or other reproductive harm. For more information, go to www.P65Warnings.ca.gov.

Lifetime Warranty

This item is backed by our limited lifetime warranty. In the event that this item should fail due to manufacturing defects during intended use, we will replace the part free of charge. This warranty covers the cost of the part only.

FREE Shipping is standard on orders shipped to the lower 48 States (Contiguous United States). Standard shipping charges apply to Hawaii and Alaska.

Shipping is not available to a P.O. Box, APO/FPO/DPO addresses, US Territories, or Canada for this item.

Expedited is available on checkout to the United States, excluding Alaska, Hawaii.

Final shipping costs are available at checkout.

Created on:

Tools used

- Loosen your lug nuts with a 19 mm socket and breaker bar Raise and secure the vehicle. Remove the lug nuts the rest of the way and set the wheel aside.

- Observe the thickness of your brake pads. Inspect your rotors for excessive wear or deep gouges. Loosen the caliper bolt with a 14 mm socket and ratchet. Use a flat blade screwdriver to compress the caliper pistons some and remove the caliper. Unbolt the 15 mm caliper bracket bolts. Remove the rotor

- Clean your new rotor with brake cleaner (mineral spirits would work just as well) Install the brake rotor onto the vehicle. Mount the caliper bracket and torque the 15 mm bolts to 85-90 ft lbs Use a C-clamp to compress the caliper. Install the brake pads, dabbing a bit of anti-seize grease on the edges to get it in. Push the caliper into place and bolt it down with your 14 mm socket. Torque the 14 mm bolt to 35 ft lbs.

- Put the wheel on the vehicle. Hand-tighten the lug nuts. Lower the vehicle. Torque your lug nuts in a star pattern to 100 ft lbs.

Brought to you by 1AAuto.com, your source for quality replacement parts and the best service on the Internet. Hi, I'm Mike Green. I'm one of the owners of 1A Auto. I want to help you save time and money repairing or maintaining your vehicle. I'm going to use my 20 plus years experience restoring and repairing cars and trucks like this to show you the correct way to install parts from 1AAuto.com. The right parts installed correctly, that's going to save you time and money. Thank you and enjoy the video.

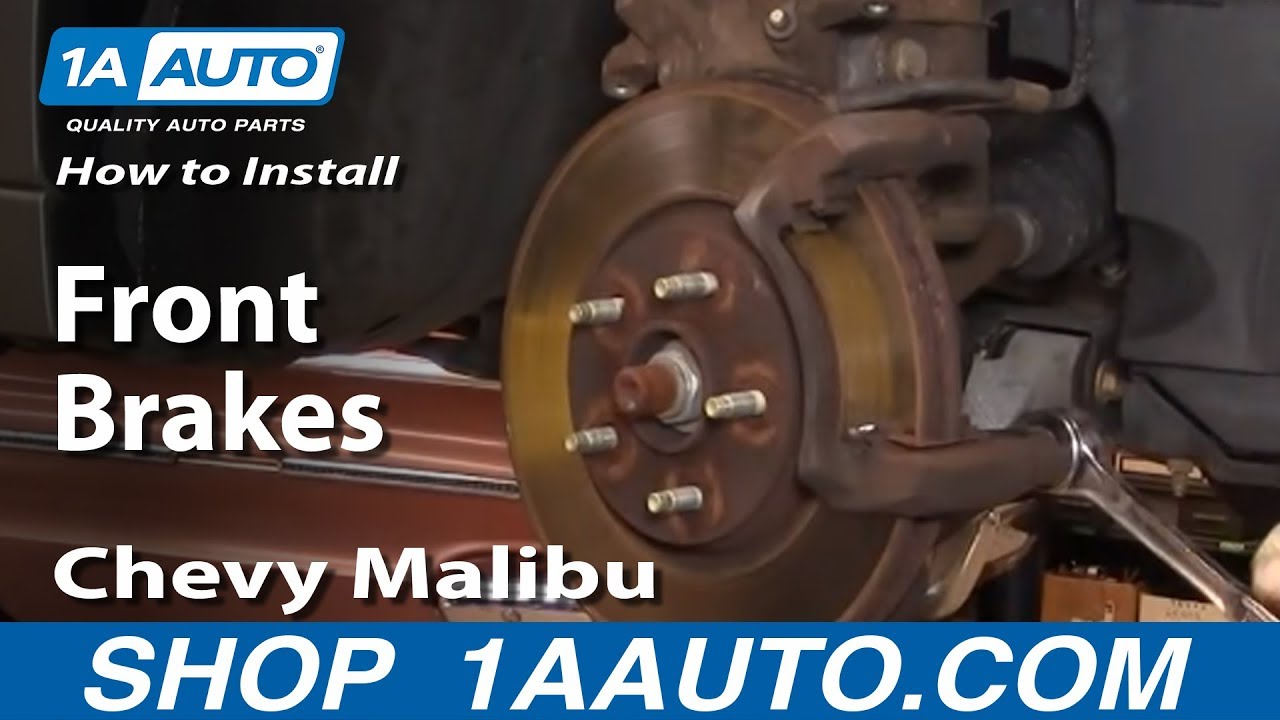

In this video, we're going to show you how to replace the front breaks on this 2006 Malibu. Procedures are the same for a few other GM Vehicles as well, the Malibu's, G5, Cobalt, HHR, Solstice and Saturn Sky as well as others. Tools you'll need are jack and jack stands, 14, 15, and 19mm sockets and that could vary by car. Ratchet with a pipe or breaker bar for some extra leverage, a flat blade screw driver, a large C-clamp, wire brush and a torque wrench. Start out by using a 19mm socket or wrench and loosen the plastic covers and then remove the wheel cover. If you don't have the benefit of air tools, you want to loosen the lug nuts up while it's on the ground then raise and support your vehicle and then remove the lug nuts on the wheel. Grab hold of the steering knuckle and turn it to make it easier to reach the back of the caliper. Now, we want to inspect the condition of the breaks. The rotors are a little crusty. As far as rust, that's not always a bad thing. You want to just take your finger and run up and down the surface of the rotor. I can feel some pretty big ridges here on the edges which indicates that this may be worn down. Also, our pads, it's hard to see but if we look in here, there's very little pad life left. You can actually tell here better. This is the metal or the pad. It's almost right up against the rotor, so this needs new front brakes. First thing we're going to do is remove these two bolts here. These two bolts are 14mm and they should come off pretty easy. I'm just going to speed it up as I remove those two bolts.

Now, this should come off, but it's pretty easy on the ridges here. What you want to do is take a good size screw driver and try out with this hold and that loosens up the caliper and the caliper comes right off, put it right there for an hour and you can just try out your pads. As you can see, here's my pad, they actually is a little wear indicator. It says there's a little bit of life left, but I'd feel better replacing these. Here's my inner pad as well. Now, we need to remove this caliper bracket. We'll remove two 15mm bolts here and here. These are going to be somewhat tighter so I'm going to use my ratchet. If you have a breaker bar, that's the best thing or use a piece of pipe, put it on your ratchet, little extra leverage and it should be apart pretty easily. We'll pop one get it started. And I'm just going to speed it up again here as I remove those bolts. I found that once I turned them, probably three or four turns, they actually came out by hand. Take the rotor, pull it right off. New rotor from 1A Auto. Put it on, take a lug nut. Kind of hold it into place here. We'll cut this off. Now, I have to reset. This piston is working its way out of the caliper, so I'm just going to take my old pad like that and take a big C-clamp and make sure we're not pressing anything lighter on the back there. I'm taking up the C-clamp, the piston goes back in to the caliper. This rubber seal kind of pops out and you just work it right back in there with your fingers. Before we put this caliper bracket, two things, I want to make sure these are sliding in and out nice and freely. Then you also want to take a wire brush and just clean out these stainless steel slide. Now, take your bracket and it goes basically between the knuckle and the disk. Put your bolt in, it will find its way. This bolt, you want to tighten up to 85 foot pounds.

New pads from 1A Auto, quite a bit thicker than what we took off there and the rear one has this rear tab. You want to make sure that's on the upside, so put that one in the back. That little tab is what makes that constant squeaking noise as your breaks wear down when they get low. Put this one up front. You want to make sure that your slides are pushed in here. Bring your caliper down right on top. Two bolts. These two bolts, you want to take into 35 foot pounds. We have the wheel back in place, then you put the lug nuts on by hand and then I'm just using my impact wrench to just tighten them up preliminary. Now with the vehicle on the ground, torque the lug nuts to 100 pounds using a star pattern. Now, put your wheel cover back on. There is a hole for the valve stem, then use a socket to tighten up the retainers. Last but certainly not the least, before you drive your vehicle, make sure you pump the breaks a bunch of times to get the pedal to feel nice and firm. You have to reset those caliper pistons, then do stops from five and ten miles an hour before you road test the vehicle.

We hope this helps you out. Brought to you by www.1AAuto.com, your source for quality replacement parts and the best service on the Internet. Please feel free to call us toll free, 888-844-3393. We're the company that's here for you on the Internet and in person.

Tools used

- Loosen the lug nuts with the vehicle on the ground Raise the vehicle with a floor jack Secure the vehicle on jack stands Remove the lug nuts Pull of the wheel If the wheel will not come off, thread the lug nuts on and strike the tire with a hammer

- Check the thickness of the brake pads Check for gauges on both sides of the rotor

- Remove the two 14mm bolts from the brake caliper Pull the caliper aside Pry the brake pads off with a flat blade screwdriver Remove the brake pad slides Clean the slides with a wire brush Apply anti-seize fluid or white grease to the slides Push the slides on with a flat blade screwdriver If only changing the pads, continue to Step 6 and install the new pads

- Remove two 15mm bolts from the brake caliper bracket Pull off the brake caliper bracket Remove the T30 Torx screw from the rotor Pull the rotor off If the rotor will not come off, thread the lug nuts and strike the hub area of the rotor with the ball end of a ball peen hammer

- Slide the rotor on Adjust the emergency brake, if necessary Put the bracket back into place, start the 15mm bolts by hand Tighten the 15mm bolts to between 75 and 80 foot-pounds of torque

- Put an old pad in the caliper Use a large C-clamp and the old pad to push the pistons back Install the new brake pads into the bracket with the wear indicator on the lower side Put the caliper on Thread the 14mm bolts by hand Tighten the 14mm bolts to between 20-22 foot-pounds If you replaced the rotor, reinstall the T30 Torx bolt Clean the rotor with brake parts cleaner or mineral spirits

- Slide the wheel into place Start the lug nuts by hand Tighten the lug nuts preliminarily Lower the vehicle to the ground Tighten the lug nuts to 100 foot-pounds in a crossing or star pattern

- Pump your brakes repeatedly until they feel firm Test your brakes at 5 miles per hour and then 10 miles per hour Road test the vehicle

Brought to you by 1AAuto.com, your source for quality replacement parts and the best service on the Internet.

Hi, I'm Mike from 1A Auto. I hope this how-to video helps you out, and next time you need parts for your vehicle, think of 1AAuto.com. Thanks.

In this video, we're going to show you how to do a rear brake job on this 2008 Chevy Equinox. This is basically the same for any Equinox and the Pontiac Torrent of this generation. Tools you'll need are jack and jack stands; tire iron or 19-millimeter socket with a breaker bar to remove the lug nuts; a 5-pound sledgehammer . that's kind of optional; our vehicle had the aluminum wheels, and they were somewhat stuck on .; 14- and 15-millimeter wrenches; a T30 Torx driver socket with a ratchet, if you are planning on replacing the rotors; a ball-peen hammer, again, for replacing the rotors; wire brush; large C-clamp; and a torque wrench.

If you don't have the benefit of air tools, you'll want to loosen the lug nuts while your vehicle's still on the ground, then raise and support the vehicle. Remove the lug nuts and wheel and tire. I'm fast forward as I remove those lug nuts. Okay, now you saw that I tried to hit it. I did put a lug nut back on and tried kicking, seeing if that can break it free. Unfortunately, it doesn't. Kicking it like that usually works, but if it doesn't, make sure you have a couple lug nuts on a few turns, big hammer, and you want to make sure you hit the tire. You do not want to hit the rim at all. Couple good hits with that.

Now you can inspect the brakes. The pads are worn pretty low. These rotors are still pretty nice and smooth. Pretty low-mileage vehicle, so they're in good shape. For now, we're just going to replace the pads, but I will show you how to take the rotor off and put it back on.

For the pads, there are two bolts. You want to loosen this bolt and remove this bolt. Bolts are 14 millimeter, and they should come off with a relatively small wrench. For this top one, you either want to use a wrench or just have a small extension for your ratchet. It's always easy to put the wrench on, hook another wrench on there. Gives you a little more leverage. Nice and smooth. Pull out on this caliper a little bit, just loosens it up. Remove this bolt down here, and the caliper just flips right up like that. Just use a regular flat-blade screwdriver to pry these pads right out. What you want to do next is, there's just these little stainless steel slides, pull those off. Then use a wire brush and clean them up really well. As soon as my slide's all cleaned up, I just put a touch of anti-seize. You can use that or some white grease. Just push these back into place. It always helps to just take a screwdriver, and make sure you push these on nice and tight. If you were just changing the pads, you put the pads back on.

If you want to take this whole rotor off, get in behind again. There are two more bolts, one here and one up there. These are 15-millimeter bolts. I'm going to use the wrench method again, just pull nice and easy until they come loose. I'm just going to fast-forward here. All I'm doing is working that wrench and removing those 15-millimeter bolts. Take that whole assembly right off.

This is a T30 Torx screw right here. If it doesn't come right off, put your lug nuts back on just a few turns. You want to use the ball end of a ball-peen hammer. You don't want to contact the rotor face. You want to hit it in the hub area. Once you see it moving, it pulls right off. Obviously, reinstall the new one. Put it on, and if the emergency brake doesn't feel a little bit resistant, you can actually adjust the emergency brake here. That can also be reached here. You could also reach that adjuster by pulling out this plug and using a screwdriver to turn that adjuster. I'll put that back on. Now put our bracket back in place. Put these bolts back in place, and then move it around a little bit until you get the bolts started. Fast-forward again here as I work those wrenches. Like I said, you put that bracket down in place, push the bolts in, and then turn them clockwise to get them started. Then I'm just working with the wrenches to tighten them up preliminarily. These should be tightened up to 75 or 80 foot-pounds. Lock my wrenches together again. Get them nice and tight.

Now you want to force this piston here, back into the caliper. What I generally do is take one of the old pads, put it right in there, a big C-clamp. Then as I tighten the C-clamp, it pushes that piston back in. Next thing you want to check is these bolts should slide back in place very easily, so just make sure they do.

Take my new pads from 1A Auto. You want to put the wear indicator, and you want to make sure it's on the down side, on the inside. Put the pads in. Make sure they squeeze together. Now to put the caliper back down, we have to push in on that side. These bolts can go back on. These bolts should only be tightened to about 20 to 22 foot-pounds, which I generally just use a wrench like this, and get them tight. Pretty much just give them a good push with this small wrench. That's usually pretty close. You see that this actually started spinning on me. I don't quite have the right wrench, so I'm just going to use a pair of pliers, make sure that's nice and tight.

Last but not least, if you did take the rotor off and replace it, put this little Allen bolt back in. Put this Torx bolt back in. Use a little brake parts cleaner or some mineral spirits to clean off the surface of the rotors.

I'll speed it up here as I put the wheel and tire back on. First, thread the lug nuts on by hand. Then tighten them preliminarily with a wrench before you put the vehicle on the ground. Torque the lug nuts to 100 foot-pounds using a star pattern. Last but certainly not least, make sure you pump up your brake pedal. Get it a good, firm pedal, then do test stops from 5 and 10 miles an hour before road testing your vehicle.

We hope this helps you out. Brought to you by www.1AAuto.com, your source for quality replacement parts and the best service on the Internet. Please feel free to call us toll-free, 888-844-3393. We're the company that's here for you on the Internet and in person.

BFA73712

877-844-3393

Monday - Friday 8:00am - 9:30pm ET

Saturday - Sunday 8:00am - 4:30pm ET

Specify your vehicle's year, make and model to guarantee fit.

This part does not fit a .