Replaces

Ford Mercury Front 4 Piece Steering & Drivetrain Kit TRQ PSA58476

PSA58476

This part doesn’t fit a . Select from parts that fit.

Specify your vehicle's year, make and model to guarantee fit.

This part does not fit a .

Frequently bought together

Specify your vehicle's year, make and model to guarantee fit.

This part does not fit a .

Part Details

- (2) Front Outer Tie Rods

- (2) Front Wheel Bearing & Hub Assemblies

- Tapered Roller Bearing

- 4 Piece

About TRQ:

TRQ is a trusted brand dedicated to making every repair a success story by combining premium parts with easy installation. Each TRQ part is engineered by a team of automotive experts to meet or exceed OEM standards, delivering enhanced performance and maximum longevity. With rigorous in-house testing, the brand ensures superior fit and function across every product line. TRQ also provides customers with best-in-class, step-by-step installation videos—so you can complete repairs with confidence, whether you're a first-time DIYer or an industry professional.

Product Features

What are Tapered Bearings and Why Use Them? Tapered bearings use rollers shaped like flat-topped cones and two races angled from the outside in of the bearing. This angle makes the bearing better at handling forces exerted on the bearing during cornering (known as axial load) in trucks and large cars. Your model came from the factory with tapered bearings. Roller ball bearings work well for smaller cars, but replacing a tapered bearing with a roller ball bearing increases wear and failure.

TRQ drivetrain kits are manufactured using premium raw materials to restore original performance. Each TRQ drivetrain component is designed to be a direct, maintenance-free replacement to the stock unit. To extend the service life of your drivetrain, TRQ recommends replacing wheel hubs, bearings, and constant velocity (CV) drive axles at the same time to ensure even wear of components and improved ride comfort. All products are fit and road-tested in our Massachusetts R&D facility to ensure we deliver on our promise of Trusted Reliable Quality.

Install Tip: When replacing steering components, have a professional alignment performed afterwards. This ensures proper tracking and even tire wear.

Our steering and suspension components are pre-greased and sealed for long life and do not require the extra maintenance typically required by greaseable versions.

Attention California Customers:

![]() WARNING: This product can expose you to chemicals including Lead and Lead Compounds, which are known to the State of California to cause cancer, and birth defects or other reproductive harm. For more information, go to www.P65Warnings.ca.gov.

WARNING: This product can expose you to chemicals including Lead and Lead Compounds, which are known to the State of California to cause cancer, and birth defects or other reproductive harm. For more information, go to www.P65Warnings.ca.gov.

Lifetime Warranty

This item is backed by our limited lifetime warranty. In the event that this item should fail due to manufacturing defects during intended use, we will replace the part free of charge. This warranty covers the cost of the part only.

FREE Shipping is standard on orders shipped to the lower 48 States (Contiguous United States). Standard shipping charges apply to Hawaii and Alaska.

Shipping is not available to a P.O. Box, APO/FPO/DPO addresses, US Territories, or Canada for this item.

Expedited is available on checkout to the United States, excluding Alaska, Hawaii.

Final shipping costs are available at checkout.

Created on:

Tools used

- Pry off the center cap with a flat blade screwdriver Loosen the 32mm hub nut Loosen the 19mm lug nuts with the vehicle on the ground Raise the vehicle with a floor jack Secure the vehicle on jack stands Remove the lug nuts Pull off the wheel

- Turn the wheel Remove the 17mm bolts from the caliper Pry the piston out with a flat blade screwdriver Lift the caliper off and secure it with a bungee cord Remove the 8mm bolt from the ABS sensor bracket Pull the sensor firmly out of the bracket Disconnect the ABS sensor Pull the ABS sensor through and out Remove the two 21mm bolts from the caliper bracket Remove the caliper bracket and brake pads Tap the rotor from the front with a hammer to break it loose Remove the rotor

- Remove the three 15mm bolts from the hub Pull the hub wiring harness out of the slot Tap out the hub Clean off the hub area with brake parts cleaner

- Apply a thin layer of grease around the hub rim Slide the hub onto the axle shaft Hand-tighten the 15mm bolts to the hub Tighten the 15mm bolts evenly Torque the bolts to 90 foot-pounds

- Attach the ABS sensor to the knuckle Clip in the ABS sensor to the clips Connect the ABS sensor Tighten the 8mm bolt to the ABS sensor bracket Apply grease to the hub Clean out the rotor with a wire brush Press the rotor to the hub Tighten a lug nut to the rotor Clean the caliper bracket with a wire brush Install the bracket to the rotor Tighten the caliper bracket bolts Torque the bolts to 122 foot-pounds Apply grease to the contact points on the clips and brake pads Press the pad into the caliper bracket Check the play in the slide pins Lower the caliper to the rotor Tighten the caliper bolts Torque the caliper bolts to 53 foot-pounds Remove the lug nut form the rotor Hand-tighten the 32mm axle nut

- Slide the wheel into place Start the lug nuts by hand Tighten the lug nuts preliminarily Lower the vehicle to the ground Tighten the lug nuts to 100 foot-pounds in a crossing or star pattern Tighten the hub nut to 184 foot-pounds Reattach the center cap

Hi, I'm Mike from 1AAuto. We've been selling auto parts for over 30 years! We're dedicated to delivering quality auto parts, expert customer service, and fast and free shipping, all backed by our 100% satisfaction guarantee. We've created thousands of videos to help you install our parts with confidence. That saves you time and money, so visit us at 1AAuto.com, your trusted source for quality auto parts.

Use a small flat blade screwdriver and pry your center cap off, and then just work your way around. Use a 32 millimeter socket and a nice big breaker bar, and you want to move hub nut. Now with your vehicle still on the ground, just loosen your five lug nuts with either your tire iron or a 19 millimeter deep socket. Raise and support your vehicle. You'll use jack and jack stands. We do have available vehicle lift. Take your lug nuts off the rest of the way and remove your wheel and tire.

Make sure your axle is free, and this one just pushes nice and easy. You don't want to hit the axle a lot with a hammer because you can mess up your CV joints. A lot of times if it is just stuck, one good hit with a hammer will break it free, and then you can push it on. Turn your wheels, and just get access to the back side. You'll want to remove the bolts that hold your caliper in place. These bolts are 17 millimeter. You want to use a good size ratchet with some leverage. Use a large screwdriver. You just want to pry the piston out a little bit. This will help you remove the caliper. The more you pry this out, the more it sets here and back in. We'll take this, and we will secure it with a bungee, so it doesn't fall down and press our lines.

Give it a little bit center bracket, which is the bolt of eight millimeter. Pick that up there. Pull this from this clip here, and also hold firmly on that cliff. Pull that up there. The ABS sensor connects right in the hood, right underneath the back of the air cleaner box right here. You probably can't see it very well, but there's just little tab. Push it on the tab and disconnect. Once you disconnect it, just pull it through. Pull the lead out and down and free. Now remove these two 21 millimeter bolts that hold the caliper bracket onto the steering knuckle.

Again, you want a good size bar for some leverage. Once all the bolts are out, your caliber bracket and shoes come out. You can also take the brake pads out of here before you reassemble. If need be, you can hit the rotor from the front just to break it loose. Because you want to be careful if you're going to hit it from the back, you don't want to put any dents or dings in it and make it unusable.

It's a good idea to consider a new set of brakes from 1AAuto.com at this point as well. Three 15-millimeter bolts hold the hub in from the back, just see through here. There's another one on the front, and then we're going to use a 3/8” ratchet and 15 millimeter socket and extension to break those free. Just turn your wheels, so you can get to that front bolt. That last bolt coming out. Now for some reason, our hub is coming out easily. I'm going to pull your harness from here. Many times, you'll have to use a hammer. Hit it from the backside where it's clear here, and bring it out. We'll use some brake parts cleaner and really clean up the hub or the steering knuckle before I call the new one.

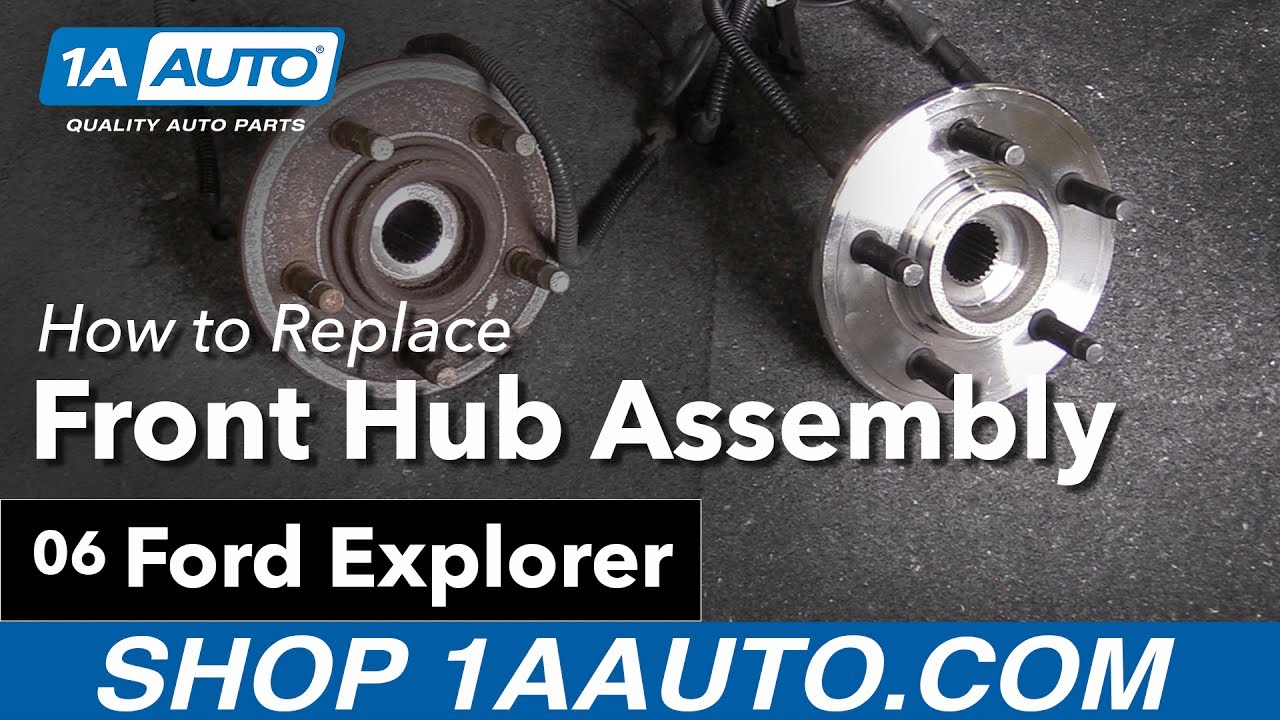

We have the original hub here on the right and our new hub from 1AAuto.com. They're all exactly the same. The ABS sensor goes in the same. All the mounting points are exactly the same, and the connector is the same. The harness has all the same grommets and moldings to mount the same way. We're going to put the new on. We're just going to put a thin layer of grease, even though you'll probably never have to replace it again. If you do, it'll come apart.

Put it on with the ABS sensor kind of towards the back top. Going to put it on the axle. Push it in, and we'll start one of the bolts in. We'll place a little thread lock on the bolts before we put them in. Now we'll use our socket and ratchet, and tighten these up evenly. You don't want to tighten one all the way. And then the other ones, bring that one in a little bit. Go to the top one, and just keep working your way around. Torque these bolts to 90 foot-pounds. Just be careful that you don't damage your CV boots. Now attach our ABS sensor. Put the armor into that clip.

This comes up here, and that touches on here. The little ear should go in there, and then the bolt goes through. Keep going up, and that clips in there. Ours has a new clip for her, so we'll pull that out and put the new clip in.I'm pointing it up through here. Find your sensor. Pull it up through, and feed it down between the AC hoses and through. Make sure it's not touching your engine, and reconnect it. Brake rotor from sticking to it too much in case you need to get the part again. Okay again, great time to consider new brakes from 1A Auto. If you're putting your old brakes on, make sure your wire brush is trying to clean that out a little bit, so it goes on nice and easy over the hub. Then we'll put a lug nut on just to hold things in place. Great to install new brakes and slides. If you're not, at least clean up the slides with a brass brush before installing the caliper bracket.

Go ahead and install the bracket. Put some intakes. Put some thread locker on the bolts. Move them in and start them. Then we're going to tighten these up and torque them to a 122 foot-pounds. Now put some caliper brake grease on the slides. Carefully not to get it onto rotor itself, inside and out. Great time for new pads from 1A Auto. If you're installing your old ones, make sure you grease the contact points. Then the one with the two circles will be your inner pad, and the pad that has kind of the M shape on it is your outer pad. Make sure that your slide pins are nice and free. If they're not, you can pull them all the way out. Clean them and grease them before you put it back together.

Take our bungee cord off, carefully lower the caliper down. If you were installing new brakes, you need to press your pistons back into the caliper. Use a C-clamp and an old pad, and press them into the caliper piston to reset it. We're reinstalling our old pads, so just put it down, or both in. These are designed so that there's a flat spot on the slide. That slides right in there and holds it in place while you tighten it. Make sure the slide is nice and flush against the caliper. You don't want it to look like that. You want it to look like that, and torque the bolts that go into the caliper to 53 foot-pounds.

Remove your lug nuts. Start your 32-millimeter nut on. You can tighten it preliminary. Best to have a new one, but you can reuse your old one.

Put your wheel and tire back in place, and start on your lug nuts, and tighten them preliminary. We'll tighten our lug nuts to a 100 foot-pounds using a star pattern, and we'll tighten our center nut to 184 foot pounds, and replace the center cap.

Thanks for watching. Visit us at 1AAuto.com for quality auto parts, fast and free shipping, and the best customer service in the industry.

Tools used

- Loosen the five 19mm lug nuts Raise and support the vehicle Remove the lug nuts Slide off the wheel

- Apply rust penetrant to the tie rod end Loosen the 21mm jam nut on the outer tie rod Remove the 19mm nut from the tie rod ball joint Tap the wheel knuckle with a hammer to loosen the tie rod ball joint stud Remove the tie rod from the wheel knuckle twist the outer tie rod off Count the number of turns it takes to remove the tie rod Hold the inner tie rod with locking pliers Mark one side of the jam nut Twist off the jam nut Count how many turns it takes to remove the jam nut

- Apply anti-seize grease to the outer tie rod and the jam nut Thread on the jam nut Apply anti-seize grease to the inner tie rod Thread the outer tie rod on the number of turns you counted in Step 2 Turn the jam rod to the edge of the tie rod Push the tie rod stud into the wheel knuckle Thread the 22mm nut onto the stud Torque the 22mm nut to 52 foot-pounds

- Slide the wheel into place Start the five 19mm lug nuts Lower the vehicle to the ground Torque the lug nuts to 100 foot-pounds in a crossing pattern

Hi, I'm Mike from 1A Auto. We've been selling auto parts for over 30 years. We're dedicated to delivering quality auto parts, expert customer service, fast and free shipping, all backed by our 100% satisfaction guarantee. Visit us at 1AAuto.com, your trusted source for quality auto parts.

In this video, we're going to be working with our 2006 Ford Explorer. We're going to show you how to remove and replace your vehicle's outer tie rod. We're doing this on the passenger side, but the procedure is the same on the driver side. If you like this video, please click Subscribe. We have a ton more information on this and many other vehicles. If you need this part for your truck, you can follow the link down in the description over to 1AAuto.com. Here are the items you'll need for this repair. Here are the items you'll need for this repair.

Using a 19mm socket and a breaker bar, loosen the lug nuts on your tire. Raise and support your vehicle. We're doing this on a lift to make it easier to show you what's going on, but this job can be done at home on a jack and jack stands. Finish removing your lug nuts. You should be able to do this by hand at this point but you can use a ratchet if you need to. You can then remove your wheel and tire.

It may be a good idea to apply some penetrating oil to whatever parts you're going to be working with. Remove the 21mm jam nut with a 21mm wrench. You really only need to crack that loose.

Remove the 19mm nut from the bottom of the tie rod end at the knuckle. We'll do this with the 19mm socket and ratchet. In order to save our tie rod end and not damage it in the removal process, we're going to use a hammer and hit the side of the knuckle right here to oblong the hole for a second and pop the actual tie rod end out. Be sure to wear proper safety equipment when doing this. Remove the tie rod end. Count the number of revolutions it takes to remove it, so we can install our new one the same way. That looks like 20 for us.

Using a pair of locking jaw pliers, clamp on to the inner tie rod and just brace it against the lower control arm. Mark one side of the nut, so you can count the number of rotations to remove that as well: 28-1/2.

Here we have our old part that we removed from our vehicle and our new part from 1AAuto.com. As you can see there are some minor differences in the size of the piece, but the threads on the inside are the same and we have the same stud and tapered end on the opposite side. If your old outer tie rod has play on the end, this ball socket can get a little bit of slop in it and create some steering and alignment issues. This new part from 1A Auto will go in direct fit just like your original equipment and fix you up right.

I'm just going to put some anti-seize lubricant on the inside of this to make sure that it's always easy to adjust, and we'll do the same thing to the jam nut. Now, our new outer tie rod is just a little bit shorter on the actual female thread piece than our original one was, so I'm just going to spin the jam nut on, and then we'll apply some more anti-seize to the threads. Now, although the actual length on the female threads here is smaller, we're going to go ahead and install it 20 turns just like we did with the part that came off: 1, 2, 3, and your numbers may be different than this. You do just want to go the same amount of rotations. All right. Put back the jam nut until it just touches the end of our outer tie rod.

Then, we reinstall it into the knuckle. Install the new nut included with your new outer tie rod. We'll tighten that down with a 22mm socket and ratchet. Torque the nut to 52 foot-pounds.

Now, when we were knocking the outer tie rod end out of the knuckle, kind of folded the backing plate here. While it's not quite touching our rotor, it's a pretty common issue. You can just take a little pair of pliers and just tweak it until it's just about the same shape as it was. You can see there's some wrinkles and stuff that have happened over the years on it anyway, but just taking that extra second to pull it away is going to keep you from getting annoying noises that can cause you frustration after you've already made your repair.

Reinstall the wheel and tire onto your hub. It's easiest to put a lug nut inside of the 19mm socket to start it onto the studs. Get all five of these down as tight as you can by hand, and then we'll torque the wheel once there's some weight on it. Lower the vehicle back down and put partial weight onto the wheel and tire. This means that you may have your jack or lift under the vehicle. Get the tire to touch and let the vehicle come down some without allowing it completely off of the lift or jack. Torque your lug nuts to 100 foot-pounds in a cross pattern.

Thanks for watching. Visit us at 1AAuto.com for quality auto parts, fast and free shipping, and the best customer service in the industry.

PSA58476

877-844-3393

Monday - Friday 8:00am - 9:30pm ET

Saturday - Sunday 8:00am - 4:30pm ET

Specify your vehicle's year, make and model to guarantee fit.

This part does not fit a .