Control Arms 101: What Do Upper and Lower Control Arms Do?

What Do Control Arms Do?

Control arms are one of the most boring yet mechanically impressive parts on a car. In the most basic of terms, the control arms allow up and down movement of the suspension while holding the knuckles, spindles, and axles firmly onto the car. They have been an integral part of suspension systems for nearly a century. Over this time, they have come in a variety of shapes, sizes, and materials, but they have always served the same exact function—to hold everything together!

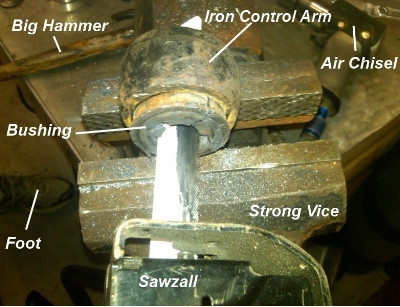

Now, you can't talk about control arms without talking about ball joints and rubber control arm bushings. The vast majority of control arms will have a rubber bushing or ball joint mounted securely to them. These allow the control arm to rotate up and down without binding up. Most ball joints and bushings are removable from the control arms with the help of a press, and are able to be replaced as needed. That being said, it's often an arduous task. Let's go back and start with the basics.

Control Arm Design

Control arm design changes as fast as automotive design and manufacturing technology does. Long ago, "double wishbone" suspension was the norm on the front of most cars. As you can imagine based on the name alone, the upper and lower control arms looked like wishbones. They were also called "A-Frames" or "A-Arms" depending on who you talked to (wishbones look like the letter "A" by the way, if you aren't familiar with poultry). This design is still common on many modern vehicles because it just plain works.

Lower Control Arms

When a vehicle has a MacPherson strut style front or rear suspension, lower control arms are the only type used. An upper control arm isn't needed because the strut takes its place. This also means one less ball joint, and a couple less rubber control arm bushings to worry about.

Upper Control Arms and Trailing Arms

For the rear of a vehicle with a solid axle, any style of control arms might be used to connect the rear axle to the frame or unibody. Most often, it is three or four control arms with rubber bushings on each end. These control arms are called "trailing arms" or "rear trailing arms". When a vehicle has independent rear suspension, it may have upper and lower A-Arms, trailing arms, or some other unique design that fits the shape of the vehicle.

Adjustable Control Arms

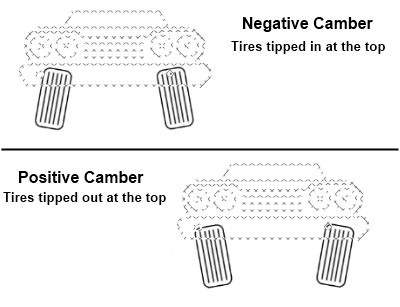

Adjustable control arms are used to adjust wheel camber. Camber is the vertical alignment of the wheels. Negative camber means that the top of the wheel is tipped inward toward the center of the vehicle. Positive camber means that top of the wheel is tipped outward, away from the center of the vehicle. Adjusting camber is a huge factor when it comes to racing, stance, and the lowering or lifting a vehicle.

When a lowering kit or a lift kit is installed on a car or truck, adjustable control arms are often needed to correct the negative or positive camber that goes along with them. If not corrected, the tires won't have the proper traction, and they will wear unevenly and prematurely. To set the camber properly with adjustable upper control arms, the vehicle needs to get an alignment by somebody that really understands what is going on. Some vehicles don't come with adjustable camber ability from the factory, so when a car like this arrives at an alignment shop and needs the camber corrected, panic can sometimes ensue.

What Are Control Arms Really Made Of?

Stamped Steel Control Arms

The oldest versions of control arms were most commonly made from stamped steel because it was cheap, fast, and easy. This style of control arm often held coil springs in place on full framed cars, and was also an attachment point for shocks and sway bars. Their major weakness is rust. When stamped steel control arms live in a wet environment, they are nearly guaranteed to deteriorate from rust. Once the rust takes over, replacing the bushings and ball joints becomes quite a challenge, and sometimes impossible without damaging the control arm. Luckily, these control arms are usually the most inexpensive to replace.

Cast Iron Control Arms

Cast Iron control arms are very popular on modern vehicles, especially trucks and SUVs. When used in front suspensions, they are often wishbone shaped, with bushings on the inside and a ball joint on the outside. They are extremely strong and can withstand harsh environments better than the stamped steel control arms. If you drive a truck with independent front suspension, take a peek under the front of it. You likely have cast iron control arms.

Cast Aluminum Control Arms

Over the years, many control arms have evolved from their humble stamped steel beginnings to elaborate cast aluminum pieces that are stronger and lighter than ever before. Being cast aluminum, they don't corrode quite like the steel control arms do, but since aluminum is a softer metal, they do bend and crack when things go wrong. This means that simple fender-benders or pot holes can potentially damage them, throwing the alignment way off.

When is Control Arm Replacement Needed?

There are many great reasons to replace a front or rear control arm assembly. The most common reason is because either the bushing or the ball joint is worn out. Replacing either of these parts individually is typically a regrettable nightmare after realizing that rust always wins, special tools are needed, and it is five times the amount of labor than replacing the entire control arm assembly. Another really common reason for a control arm replacement is due to improper towing of the vehicle. Some inconsiderate tow trucks will latch their hooks onto a control arm which easily bends it into a pretzel. This is quite thrilling because it isn't always obvious that it is bent immediately after. Usually the car will have a slight pull in one direction or the nearest tire will start wearing in a strange fashion. Diagnosing this can be a bit tough, too, because the control arm assembly may look completely fine, until you compare it to a new one. When you do, the "AH HA!" moment happens, and the world becomes a better place. The last good reason for a control arm replacement is due to an accident. Whenever a vehicle suffers damage to the wheel area, control arm damage is inevitable. Although they are extremely strong, they don't stand a chance of staying straight during an impact.

Replacing Control Arms

Different vehicles have different degrees of difficulty when it comes to replacing control arms. In most cases, replacing a whole control arm assembly is far easier than replacing a single ball joint or a set of control arm bushings. Without the right tools, a bushing replacement will get out of hand very quickly. Before you know it, air chisels and Sawzall's are waking up the neighborhood and your vice is broken. Replacing the entire control arm assembly is definitely the way to go. Now, some control arm repairs can be a leisurely thirty minute job easily done in a driveway. Others may require more labor, compressing coil springs, or use of special tools. If it is your first time replacing something of this nature, having access to a service manual would be extremely helpful, or check out our how-to videos for instructions on your year, make, and model.

Need a Replacement Control Arm?

You have come to the right place if you are in need of a control arm replacement. We carry a massive and ever-expanding selection of

front and rear, upper and lower control arms for thousands of car and truck applications. Many are also available in suspension kits which will bring your entire suspension back to new again. We use these control arms on our own daily drivers and classic cars, and we have absolute confidence in the fit, finish, and quality.